How Regina Industries' precision-made vials contribute to global scientific discovery

Drosophila Vials: Supporting the First Steps Towards Tomorrow's Cancer Breakthrough

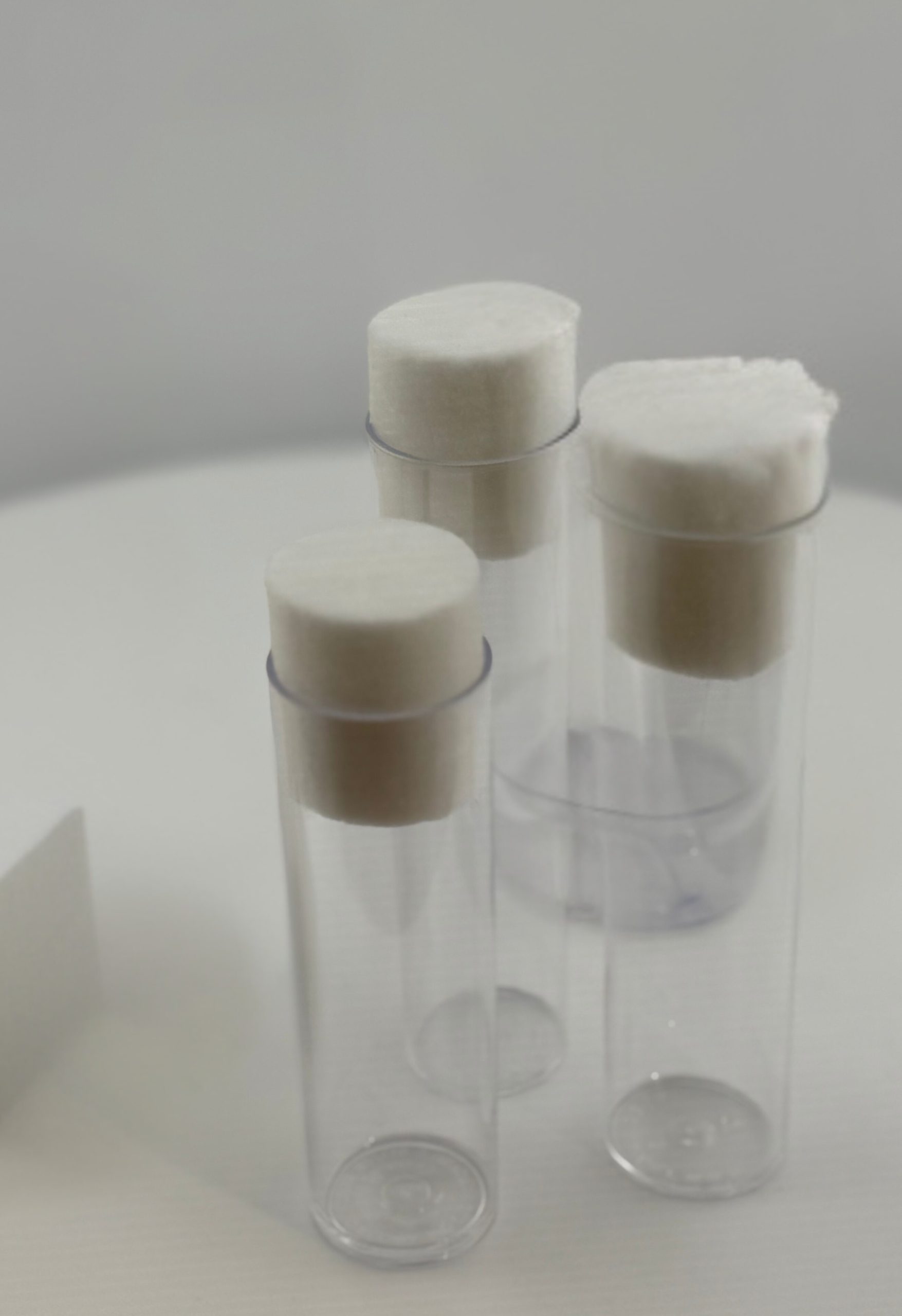

In modern biomedical research, some of the most ground-breaking discoveries begin with tools so simple that they’re often overlooked. One of these tools is the drosophila vial—a lightweight, precisely manufactured container used to house Drosophila melanogaster, the common fruit fly.

At Regina Industries, we produce high-quality drosophila vials that support laboratories, universities, and pharmaceutical research facilities around the world. These vials play a small but vital role in scientific studies that ultimately help researchers understand diseases and develop new medical treatments, including those related to cancer.

By Amber-Louise Gregory

Why Drosophila Matters in Cancer Research

Drosophila may be small, but they are one of the most powerful model organisms in modern science. Their unique advantages include:

– Genetic similarities to humans in many key biological pathways

– Fast reproduction cycles, enabling rapid experimental results

– Highly controlled, stable laboratory environments

– The ability to study gene function, mutation effects, and cellular behaviour

Because many of the pathways involved in tumour growth, DNA repair, and cellular regulation are conserved between fruit flies and humans, drosophila research provides essential early-stage insights that guide more advanced studies.

This makes drosophila vials – simple as they appear – the first container in which the earliest clues to future cancer therapies begin.

Precision Vials for Reliable Scientific Results

Regina Industries manufactures drosophila vials with the consistency and quality required for research environments. Our vials offer:

– Uniform internal dimensions to support consistent airflow and humidity

– Smooth, clears surfaces that prevent contamination

– High clarity for easy observation of flies and developmental stages

– Durable materials that withstand repeated handling and temperature variation

– Compatibility with stoppers, food media, and lab automation systems

Even the smallest variation in shape or material can influence the behaviour or survival of a drosophila population. That’s why our vials are engineered with controlled precision to ensure dependable and reproducible research outcomes.

The First Steps in Developing Future Treatments

While drosophila vials are a simple piece of laboratory equipment, they are part of the earliest stages of research pipelines that can lead to:

– Understanding how cancer-related genes behave

– Studying how cells divide, mutate, and repair themselves

– Identifying potential drug targets

– Testing biological responses before moving to advanced models

Every major breakthrough begins with foundational experiments, and drosophila research is often where those first insights are discovered. Regina Industries is proud to support scientists working at the front line of medical innovation.

Trusted by Research Institutions and Pharmaceutical Developers

Our drosophila vials are used by:

– University biology and genetic departments

– Pharmaceutical R&D labs

– Biotechnology firms

– Cancer research organisations

– Independent research laboratories

Researcher choose Regina Industries because they can rely on consistent, clean, and durable vials that eliminate variables and support accurate scientific results.

Supporting the Future of Medicine Through Precision Manufacturing

From simple laboratory containers to complex engineered components, Regina Industries understands the importance of precision, reliability, and consistency in every product we create. Our drosophila vials may be small, but they support some of the most impactful scientific work happening today.

By providing dependable equipment to research worldwide, we’re proud to contribute to the early stages of discoveries that may one day become life-changing medical treatments.

Continuous Collaboration

Our work doesn’t stop when parts leave the factory. We maintain ongoing support, regular review meetings, and efficiency tracking to help refine future batches, adapt tool maintenance and optimise production — so you remain competitive and your products stay superior.

What Regina Offers You

Choosing Regina Industries means partnering with a company that boasts over 75 years of expertise in precision engineering. Our commitment to quality is backed by our ISO 9001:2015 certification, ensuring that every project meets the highest standards of reliability and consistency.

-

Competitive pricing for subcontract turning work

-

Full project consultation & quoting (materials, finishes, tolerances)

-

Reliable scheduling & logistics — we understand deadlines matter

-

Quality assurance, inspection, and documentation per your standards

-

Flexible batches — from one-offs to ongoing production

Let's Bring Your Project to Life

Are you ready to elevate your next project with precision and efficiency? Whether it’s large plastic moulded parts or intricate prototypes, Regina Industries is here to help. Reach out to us today to discover how our advanced capabilities and commitment to excellence can benefit your business.